Current Bottlenecks With COVID-19 Testing

Four months into 2020, COVID-19 has changed the world. Currently, the US and Europe are the epicenters of the disease with cases and deaths rising exponentially while many countries have imposed strict lockdown measures in order to try to control the spread of the disease.

Through these trends, the only country that has been successful at “flattening the curve” is South Korea. They have managed to control the outbreak without instituting the strict lockdowns that have been seen in nearly all countries around the globe.

The South Korean success story can be attributed to one strategy in particular: testing.

South Korea was able to institute a massive testing campaign that identified and isolated those who were positive. They created drive-thru testing locations, customized phone booth testing locations, deployed biotechnology companies to scale up reagent manufacturing, and tracked mobile phone data to determine the past whereabouts of COVID-19 positive patients.

All of this was critical since it can take up to 14 days for someone who has the virus to show symptoms. Due to this long incubation period, testing is crucial in controlling the spread of COVID-19. Widespread testing allows us to identify and isolate those who are positive and prevent them from spreading the virus.

“The testing they did in South Korea was very important in controlling their outbreak,” said Dr. Angela Caliendo, an infectious diseases professor at Brown University’s Alpert Medical School. These strategies were so successful in curbing the spread of COVID-19 that as of March 2020, over 100 countries have asked South Korea to assist with their testing programs.

This system of rampant testing resulted in 4099 tests being administered per million people in South Korea by March 9th. By comparison, the US has lagged behind in testing quite considerably. Even though the two countries had their first case of COVID-19 at very similar dates – January 15th for the US and January 20th for South Korea – the US had only administered 26 tests per million people by March 9th. The effects of this can be seen now in the total number of COVID-19 cases. South Korea has had 196 total cases per million people while the United States has 741 total cases per million people.

Effective, widespread testing is crucial to controlling the spread of COVID-19. However, there have been many issues and bottlenecks in getting the scale of testing to where it needs to be. The current system in the United States is dysfunctional and is not allowing the development of an adequate response to the COVID-19 crisis. Below, each step in the typical COVID-19 testing workflow is detailed along with the obstacles that need to be resolved in order to expand testing and save more lives from this disease.

Sample Collection

The first step in testing is to collect a sample. A patient has to go to a hospital, clinic, or testing center/drive-thru and meet with a healthcare professional who performs the sampling. With a sterile swab, the healthcare worker takes a nasopharyngeal (inside the nose) or oropharyngeal (back of the throat) sample. In swabbing these areas, the goal is to collect any biological material that has recently been within the lungs (where COVID-19 replicates). Once collected, the swab is stored and transported/shipped at 2-8 °C or at -70 °C on dry ice to a clinical testing lab.

At first step in the testing workflow, there are several issues that need to be resolved in order to streamline the process.

Shortage of Swabs

The biggest problem is that the United States doesn’t have enough swabs available to collect samples from everyone who needs a test. The shortage of swabs is due to the increased demand around the globe, as swabs are needed for most COVID-19 testing.

Swabs, in particular, have an exacerbating circumstance. Copan, one of the largest manufacturers of swabs, is located in Lombardy, Italy, which was hit very hard by the virus which limited the global supply of swabs even further. Although Copan has been allowed by the Italian government to continue production amid the countrywide lockdown, they will still need to generate millions of swabs in order to meet the demand for COVID-19 testing in the United States.

The other problem with swabs is that they have to be used properly in order to yield accurate results. The correct technique requires the swab be inserted deep within the nose or throat and rotating the swab several times (which is not a comfortable experience for the patient). If the swab does not pick up enough of the virus, it will lead to a false negative result. Studies from China have shown that the false negative rate can be as high as 30%.

While nasopharyngeal swabs are the most commonly used method to collect patient samples, other sample sources can be processed just as easily. The FDA states that the COVID-19 diagnostic panel can be tested on upper and lower respiratory specimen samples which includes sputum. Sputum, or phlegm, is the mucousy substance that is secreted by cells deep within the respiratory tract. Since sputum samples are produced by the patient from deeper within the respiratory tract, it is more likely to pull up the virus from where it resides compared to swabs. The swabs can only reach the back of the throat or nasal cavity whereas sputum is expelled from deeper within the respiratory tract, giving a higher chance for the viral particles to be collected.

Recent studies have supported this by showing that sputum and fecal samples were able to return more positive COVID-19 results than swabs. These findings indicate that rate of false negatives may decrease with the adoption of sputum sampling.

In order to expand and improve the testing system, there needs to be more methods of sample collection. Currently, swabs are the only devices that have been approved for use by the FDA, but approving new collection devices for use could solve stock issues with sample collection devices and could potentially lead to more accurate test results.

Higher Risk of Infection

Current sample collection methods have healthcare workers collect a sample directly from the patient. This requires close contact with the patient and puts the worker at a greater risk of infection. This issue is only compounded by the shortage of PPE at many hospitals and testing locations.

This particular portion of the COVID-19 testing workflow is slowly changing with many hospitals and testing sites taking actions to protect their workers from the disease. Firstly, the FDA has announced that self-administered testing, under the supervision of a healthcare worker, is allowed at testing locations for symptomatic patients. This helps protect healthcare professionals from having direct contact with the patient. A study by United Health Group found that of 500 patients who self-administered swab collection tests, COVID-19 was detected in more than 90% of positive patients, which was consistent with the clinically administered test.

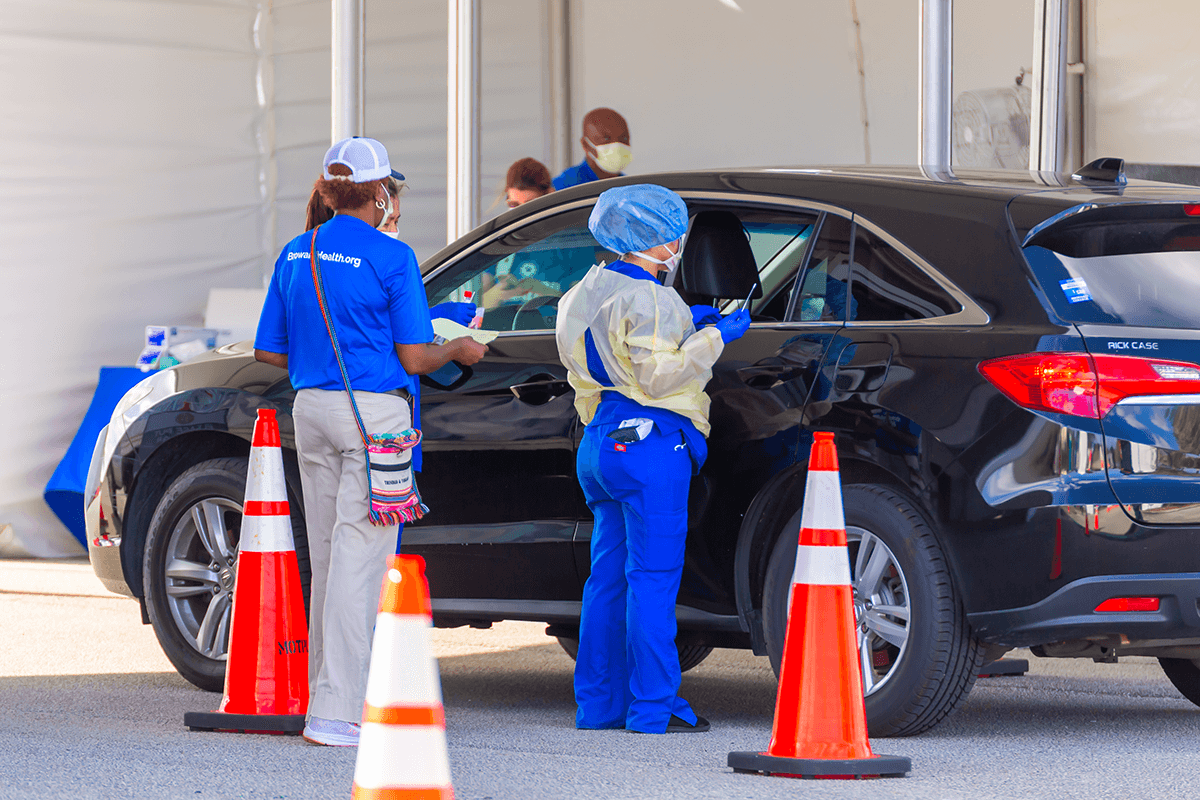

Other solutions have included drive-through sample collection sites which allow potentially infected patients to stay isolated in their cars, away from other patients and workers. This eliminates the need for patients to enter the hospital for COVID-19 testing and risk infection by sitting in a crowded waiting room of symptomatic patients to deliver their sample.

The last solution that could further protect clinicians and patients would be to keep the potentially infected people away from the healthcare facilities by performing sample collection at home. This would entail the collection device being mailed to the patient who then self-administers the test and then mails it back to a lab for processing. Currently, the FDA has not authorized any at-home testing or sample collection for COVID-19, but has been sent proposals from several companies.

One of the biggest reasons for the slow approval has been concern that patients are not able to self-collect samples correctly. While instructions on how to collect samples may help to reduce confusion for the general public, the FDA needs further proof that patients are able to collect samples at home without increasing the risk for false-negatives.

Another is reason for the delays in approval lie with the stability of the sample during shipment. The COVID-19 test detects the RNA from the virus, and because RNA tends to be much less stable than DNA, there is a concern that the RNA can degrade. If this happens, the RT-qPCR would not be able to amplify the viral RNA and the test would be negative.

Because of this, it is crucial that the appropriate stabilization reagents are used in potential at-home collection workflows. They can prolong the stability of the RNA for up to 30 days at ambient temperatures meaning that samples can be effectively collected and transported without worry of a false negative result. By stabilizing the RNA, these reagents are able to detect very small amounts of the virus allowing more sensitive assays to be performed.

As we continuously optimize the testing workflow, these considerations need to be taken into account in order to effectively protect both clinicians and patients.

RNA Extraction for COVID-19 Testing

Once the sample arrives in the lab, the RNA needs to be purified from the sample with an extraction kit manually or with an automated liquid handler.

Shortage of RNA Extraction Kits

Just like swabs, there is a dramatic shortage of the reagents required to purify and analyze the viral samples for COVID-19 testing. Once the patient sample arrives in the lab, the RNA needs to be extracted. This process requires a series of chemical buffers that lyse, bind, and purify the viral RNA. Some labs make their own reagents to extract RNA, but most use commercial kits that take hours off the processing time.

With the increasing demand for COVID-19 testing, many labs are struggling to find reagents from their suppliers that are required to process the test. This then delays test results and increases the risk of further spread of the virus as patients may assume the delayed result means they are negative for COVID-19.

The situation has gotten so bad that some scientists have taken to twitter to request donations from other scientific labs. Since the RNA extraction kits are used in a wide range of applications, there were several labs, companies, and research institutes that were not analyzing COVID-19 that could help offset the critically low level of extraction kits.

As one of the largest manufacturers of RNA extraction kits, Zymo Research has increased their manufacturing capabilities to help support the massive need for additional reagents. They will be producing enough of their kits to enable millions of coronavirus tests each month.

COVID-19 Detection

The purified samples contain the host RNA and any COVID-19 RNA (if present). To detect the viral RNA in the sample, a molecular biology technique called real-time reverse transcription polymerase chain reaction(rRT-PCR). This system amplifies the small amount of viral COVID-19 RNA present to thousands of copies, so that may be detected. This makes this assay extremely sensitive.

If there is no virus present within the sample, there will be nothing for the rRT-PCR to amplify and the machine will show a negative result.

Shortage of Reagents

Like with all other supplies in the testing workflow, the detection reagents for the rRT-PCR are also in short supply. There are shortages of the detection buffers, dyes, and enzymes will that dramatically slowdown the time to get results to patients.

Scaling Up

Typically, when a lab begins to process a high number of samples they turn to automated solutions and move away from processing samples by hand. This is done by robotic platforms that greatly increase the throughput of a lab, allowing hundreds or even thousands of samples to be processed in a single day.

Stalled Implementation of Automation

As the testing demand for COVID-19 has grown, it has strained processing labs, and many of these laboratories are looking toward high-throughput automated workflows to keep up with the flood of patient samples that need to be processed. However, these automated workflows usually require lengthy amounts of time before a lab can fully utilize the machine because it has to be set up appropriately.

First, the machine needs to be delivered and installed. Since these are large and sensitive pieces of equipment, this process can take up to a week. Once the robot has been set up, every movement of the robot has to be coded in (or scripted) so that it can manipulate the samples appropriately and isolate the viral RNA. Just like coding an app on your phone, the scripting process is very detailed and time-consuming. Every movement of the robot has to be detailed and entered into the machine: the volume of reagent added at each step, where the reagent is dispensed, how many times the sample should be mixed, and more. Once these commands are correctly entered into the liquid handler, the script has to be tested and then optimized as needed.

From here, the script needs to be validated with test samples to ensure the device can function properly. Once it has been validated, the lab can finally begin processing patient samples on the machine.

This process is time-consuming and arduous for many labs and can take several weeks to complete from the time the device is purchased to the first patient samples being processed on it. In the COVID-19 era, these delays simply hold back labs from testing as many samples as they need to.

The best solution to avoid these delays in implementing automation is to use an automated liquid handler that comes preloaded with scripts that have already been configured and optimized for viral RNA extraction, like the DreamPrep NAP. This device delivers a load-and-go system with a user-friendly interface that dramatically decreases the amount of time needed to begin processing samples. With this device, labs can quickly and easily scale up their operations to accommodate testing for a much higher number of COVID-19 samples.

--

In the world of biology, this workflow is not very complicated. Theoretically, this workflow could function seamlessly with samples flowing in from patients and being processed by the lab with results delivered in 1-2 days. However, the global pandemic has placed a severe strain on the entire testing workflow. Just as with hospitals being overburdened and reaching capacity, testing labs around the world are feeling this same effect. Because of this, there is a severe delay in the implementation and expansion of critical testing services, which adds days to the processing time.

This strain on the testing system is unlike anything the field has ever seen. The industry needs rapid implementation of new solutions to combat the virus from all angles.

With scientists around the world working feverishly to expand production, implement new testing workflows, and streamline processes, the United States is slowly ramping up the amount of tests that can be administered. However, none of these tactics will be effective without the help of the public. Just as the public can flatten the curve for hospitals by staying home, that same effect applies to testing laboratories. With most of the public staying home, they are already helping to resolve the testing bottleneck by decreasing the number of samples that need to be processed. As the world comes together to fight the virus, every single person has a part to play.